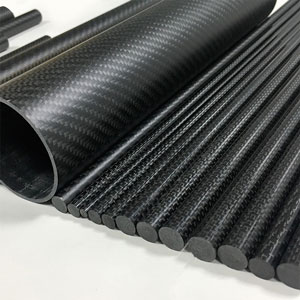

Tubes & Rods

CFG mastered the mature and efficient composite molding, bagging, inflation, winding, hot compression, autoclave, and other molding processes. We produce different specifications of carbon fiber round tubes, square tubes, bent tubes, shaped tubes, etc. Carbon fiber tube is a typical advanced product in composite materials, made of carbon fiber and resin, which is widely used in parts of drones, inspection tools, guide rollers, sports gears, etc. So, how is the performance of carbon fiber tubes compared with metal tubes? Is it possible to replace the use of steel pipe, the following to give you an analysis of the performance of carbon fiber pipe and steel pipe comparison:

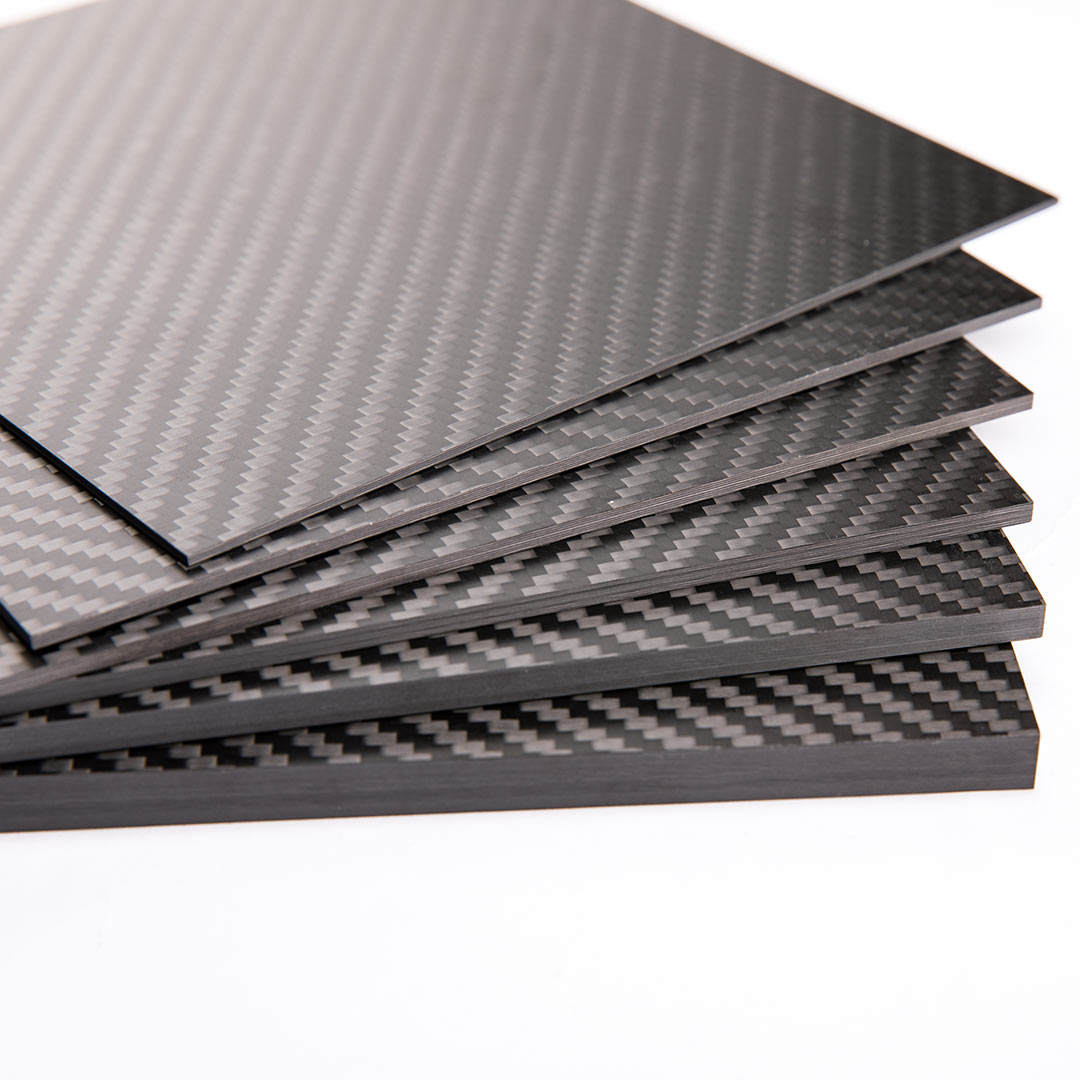

Ø Strength: the tensile strength of carbon fiber is 3000 Mpa, and the strength of carbon fiber tube made of resin composite is about 1500 Mpa, while the tensile strength of metal pipes, steel tube is 300~600 Mpa, and the tensile strength of aluminum tube is 110~136 Mpa.

Ø Weight: the density of carbon fiber tube is only 1.6g/cm³, the density of steel tube is about 7.8g/cm³, and the density of aluminum tube is 2.7g/cm³. The lighter the weight, the more obvious the weight reduction, which contributes to the efficiency of the product.

Ø Fatigue resistance: the fatigue strength limit of ordinary metal tube is 30%~50% of its tensile strength, while the fatigue strength limit of carbon fiber tube is 70%~80% of its tensile strength, thus, the carbon fiber tube is more stable than metal when working under long-term alternating load conditions and has a longer service life.

Ø Thermal expansion: The coefficient of thermal expansion of aluminum is 23x10^-6, steel is 13x10^-6, while the coefficient of thermal expansion of carbon fiber is almost negligible, about -1.4x10^-6. The stability is excellent. With the use of special resins, the maximum operating temperature of carbon fiber tubes can reach 220-260 ºC, and military grade resins can reach 1000ºC.

Contact us for a free sample!